In the ever-evolving sector of industrial power transmission, there’s a high demand for components that are reliable, efficient, and durable. SKF industrial belts are at the forefront in this area. This article explores the role of SKF industrial belts in various industrial settings, emphasizing their importance in meeting the challenging needs of the mechanical sector.

Understanding the Role of SKF Industrial Belts

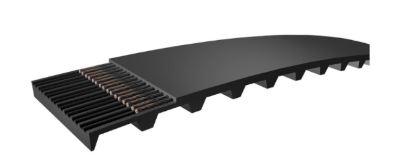

SKF industrial belts play a pivotal role in the functionality of power transmission systems, serving as their fundamental component. These belts are meticulously designed to facilitate efficient power transfer, embodying a harmonious fusion of innovative design and advanced engineering expertise. The use of high-quality materials, including wear-resistant wrapping fabric, coupled with state-of-the-art manufacturing techniques, is a testament to SKF’s commitment to excellence. This approach guarantees that SKF belts not only offer superior longevity but also maintain consistent performance under various operational conditions.

The significance of SKF industrial belts extends beyond their durability and efficiency. They are designed to cater to varied industry requirements, ranging from automotive to heavy machinery. This versatility is achieved through a careful selection of materials and a design process that takes into account the unique demands of each application. As a result, SKF belts are not just components; they are integral solutions that enhance the overall efficiency and productivity of the systems they are part of.

Moreover, SKF’s focus on innovation is evident in their continuous efforts to improve belt technology. By investing in research and development, SKF ensures that its industrial belts are at the forefront of technology, offering features such as reduced noise levels, minimal maintenance requirements, and improved energy efficiency. These advancements not only benefit the end-users in terms of operational cost savings. It also contributes to a more sustainable and environmentally friendly industrial landscape.

SKF Industrial Belts: Essential Characteristics

Enhanced Performance and Longevity: Designed for superior functionality, SKF industrial belts are made with materials that withstand oil and heat. This quality ensures their reliable performance in various temperature ranges, making them suitable for multiple industrial applications, especially in challenging environments.

Innovative Construction: SKF belts, including the classical and SKF V belts, feature a design that balances oil resistance. This innovative construction not only boosts their lifespan but also guarantees steady power transfer, even in demanding tasks.

Adaptability: The adaptability of SKF industrial belts is noteworthy. They are applicable in a wide array of settings, from small-scale machinery to extensive industrial systems, adeptly managing diverse power transmission needs.

Usage of SKF Industrial Belts in Various Mechanical Sectors

SKF industrial belts are utilized across a variety of sectors within the mechanical industry. Their importance is highlighted in scenarios demanding the utmost precision and effectiveness. Key uses of these belts include:

- Material Handling via Conveyor Systems: SKF belts are instrumental in facilitating the seamless and uniform transport of materials in conveyor setups.

- Power Transmission in Pumping Systems: These belts are vital in transmitting power effectively in pumping systems, ensuring their efficient functioning.

- Operational Efficiency in HVAC Systems: In systems related to heating, ventilation, and air conditioning, the role of SKF belts is critical for sustaining high operational efficiency.

Benefits Compared to Rival Products

SKF belts stand out in the industrial belt sector due to multiple benefits:

Enhanced Durability: The resistance to wear and tear in SKF belts extends their service life, minimizing the frequency of replacement.

Improved Energy Conservation: Engineered for optimal power transmission with less energy loss, these belts contribute to increased energy conservation.

Lowered Maintenance Expenses: The robustness and dependability of SKF belts result in decreased maintenance expenses for industrial operations.

Caring for SKF Industrial Belts

Ensuring the longevity and optimal functioning of SKF industrial belts involves dedicated care and maintenance. These belts are recognized for their robustness and high performance, but they still need consistent upkeep. Here are key steps for maintaining your SKF industrial belts:

Regular Inspections: Begin with thorough inspections of the belt and its pulleys, checking for signs of wear, such as cracks, fraying, or any damage.

Appropriate Tensioning: Maintaining the right tension is crucial for peak performance. Avoid over-tensioning to prevent excessive wear and potential breakage and avoid under-tensioning to prevent slippage and loss of efficiency. Use a tension gauge or adhere to the manufacturer’s instructions for correct tensioning.

Alignment Verification: Ensure the belt and pulleys are aligned correctly to avoid uneven wear and reduced efficiency. Use a laser alignment tool or a straight edge for precise alignment.

Keeping Clean: Regularly clean the belts and pulleys to restrict and remove the dust, dirt, and other contaminants that can impair the belt’s grip and lead to early wear. Use a suitable cloth or brush for cleaning.

Lubrication of Pulley System: While the belts don’t need lubrication, the pulley system’s bearings should be lubricated according to the manufacturer’s guidelines to minimize friction and wear.

Environmental Factors: Store extra belts in a cool and dry atmosphere away from direct sunlight and chemicals to prevent material degradation before use.

Proper Handling and Storage: Handle belts carefully to avoid damage. Don’t fold or twist them. Store them either hung on a rack or loosely coiled to avoid deformation.

Strategic Replacement: Implement a proactive belt replacement strategy. Regular usage monitoring and scheduled replacements can help avoid unexpected operational halts.

Training for Personnel: Ensure that staff handling the belts are well-trained and knowledgeable about maintenance best practices to significantly increase the belts’ lifespan.

Seeking Expert Advice: For any uncertainties regarding belt maintenance, consult professionals. Regular expert check-ups can aid in maintaining the belts’ top performance.

SKF’s Pledge to Progressive Development

SKF prioritizes staying ahead in technology with its industrial belts, focusing on efficiency and environmental sustainability. This commitment is reflected in their ongoing investment in research and development.

Final Thoughts

Combining innovation, quality, and performance, SKF industrial belts stand out in various industrial applications. Renowned for their efficiency, durability, and reliability, these belts are an excellent choice. For those interested in exploring SKF’s range of industrial belts and their power transmission solutions, a visit to Bearing World is recommended. Our selection includes top-notch bearings from European, Japanese, and various cost-effective brands, catering to diverse customer needs. We offer technical support, training courses, and timely delivery, aligning with industry benchmarks, establishing us as a reliable bearing supplier in Saudi Arabia.